quem somos?

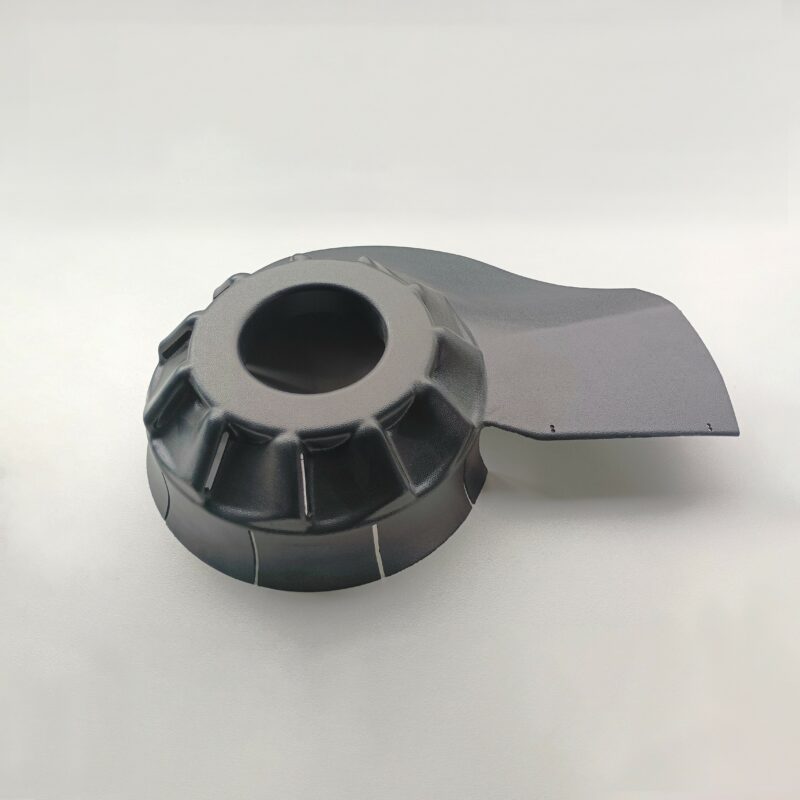

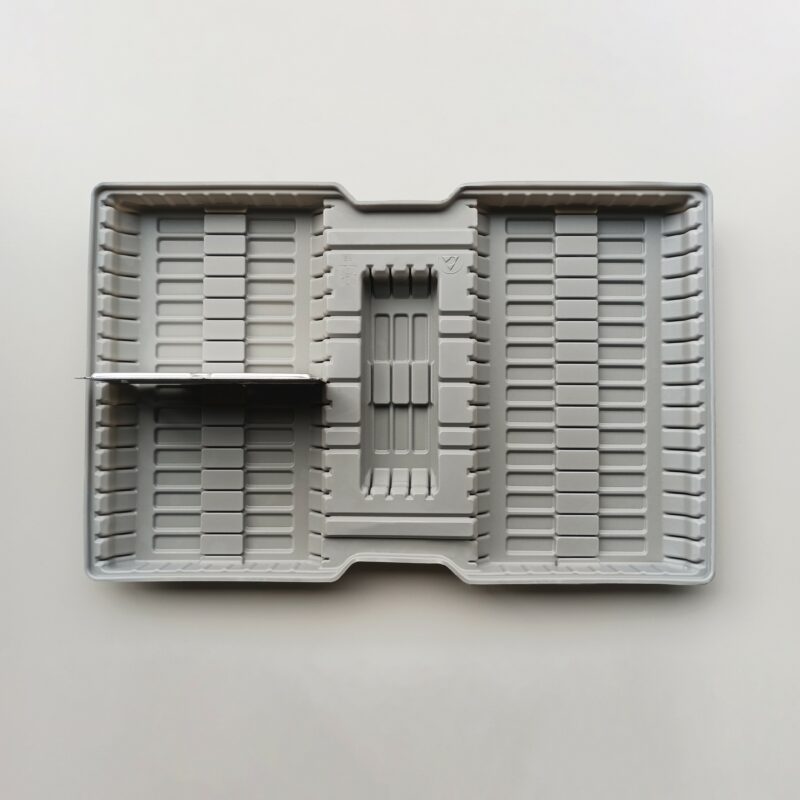

Somos uma empresa transformadora, com mais de 17 anos de experiência na moldação de plásticos pelo processo de termoformagem a vácuo, para diversos fins e indústrias.

serviços

Conheça os nossos serviços e descubra como podemos termoformar as duas ideias…

• Complementaridade de projetos de termoformagem

• Desenvolvimento de Produto Final e ferramentas de Produção;

• Desenvolvimento de Projeto CAD 2D e 3D;

• Corte Laser 2D de diversos plásticos e madeiras;

• Reforço estrutural com peças termoformadas em material 100% reciclado.

PRODUTOS

Contamos com um portfólio de produtos bastante versátil, que procura abraçar cada oportunidade e exigência dos mais diversos setores e indústrias…

• Logística Industrial/Embalagem

• Transportes

• Setor Agrícola

• Setor Hospitalar

• Setores Industriais diversos